Sustainability

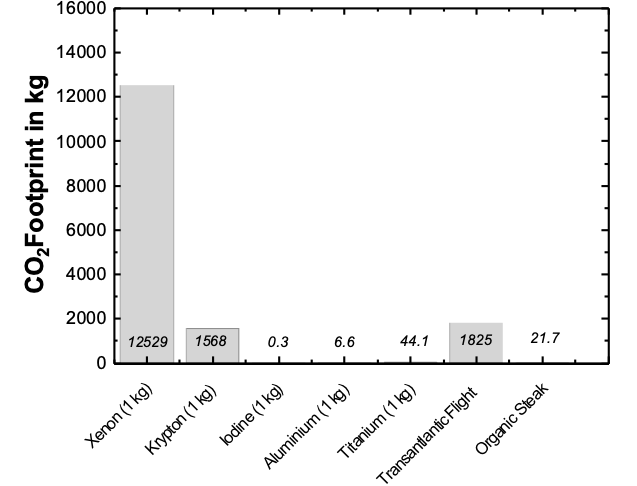

As opposed to noble gas extraction, iodine can be effectively recycled from industrial waste products with a negligible energy consumption. Selecting iodine as a green propellant offers a way to significantly lessen the environmental impact, as life cycle assessments are becoming standard even for satellite missions. Recycled iodine even meets all pharmaceutical standards and additionally it is gathered and recovered in the recycling facility for ground testing, completing a closed cycle.

Strategic

Ensuring that Europe is self-reliant in space access and the technologies needed for sovereignty and strategic autonomy is a key strategic goal. This project is more sustainable because it relies on a fully European supply chain, the participants own all the necessary patents, and it does not depend on non- European technologies. This way, the project can protect the budget, the commitment, and the resources that the participants have invested.

Excellence

Linked to their strategic advantage, the iFACT-MP project seeks to showcase European leadership in iodine EP and expand it to the mid-power (3-5 kW) range. To achieve this goal, the project unites major European research institutions and experts for iodine thruster development, electride emitter development, iodine EP testing, optical flow diagnostics and space-grade PPU and fluidics development.

Economic

The project aims to achieve this objective through several critical steps. These include the development of a robust 3-5 kW iodine ACFT subsystem, enhancement of the C12A7 emitter technology to establish a fully iodine-based EP chain, validation of essential iodine building blocks for future in-orbit demonstration and market integration, and the establishment of an independent European test facility dedicated to iodine testing and benchmarking. By meticulously navigating these milestones, the iFACT-MP project is poised to fortify European prominence and proficiency in iodine Electric Propulsion, securing a pivotal role in the evolving landscape of innovative space technologies.

Performance

A unique iodine feeding system will be built in line with flight standards, including the requisite verification, justification, and formalization of the fluidic design, as well as barrier requirements. This will also include processes for iodine fueling and integration into the satellite. Because of the heat control required for iodine feeding, the operational procedures and error handling to avoid unwanted iodine condensation will also be evaluated throughout the Power Processing Unit (PPU) breadboard development and endurance test. After the activity, the test facility, which can test iodine thrusters with up to 5 kW of power, will be available, promoting further iodine EP development in Europe.